Basic Info.

Model NO.

HKD1000

Standard

Standard

Application

Tank

Size

86 Type

Certification

ISO, CE

Transport Package

Cardboard Box

Specification

50.00cm * 50.00cm * 30cm

Trademark

Vacorda

Origin

China

HS Code

9026100000

Production Capacity

300 Pieces Per Week

Packaging & Delivery

Package Size

50.00cm * 50.00cm * 30.00cm

Package Gross Weight

3.000kg

Product Description

Working Principle

The RF admittance level instrument is developed from the capacitive level measurement technology. It is a level control detection instrument with anti-hanging material, more reliable, more accurate and wider applicability. RF admittance is a combination of resistive, capacitive, and inductive components.

RF admittance level control technology is to achieve level measurement by measuring the admittance of the measured medium with high frequency radio waves. The difference between RF admittance technology and capacitive technology lies in the diversity of measurement quantity and three-electrode technology. A shield electrode is added between the measurement electrode and the ground electrode to protect the halo electrode from the influence of the hanging material, and the measurement is more stable. Accurate and reliable.

When the position of the material changes, the three-electrode signal processing circuit compares the comprehensive change signal of impedance, capacitive reactance and inductive reactance with the reference signal. When the difference between the two signals reaches a certain level, the output state of the relay changes, thereby detecting Level changes.

Features

Application

Selection table

HKD1000-1 2 3 4 5 6

For example: HKD1000-11S1AP1S100, Standard type, installation for 1-1/4"NPT thread, 220VAC power supply, Wetted material for SS304, Working temperature<400ºC, Probe length=100mm.

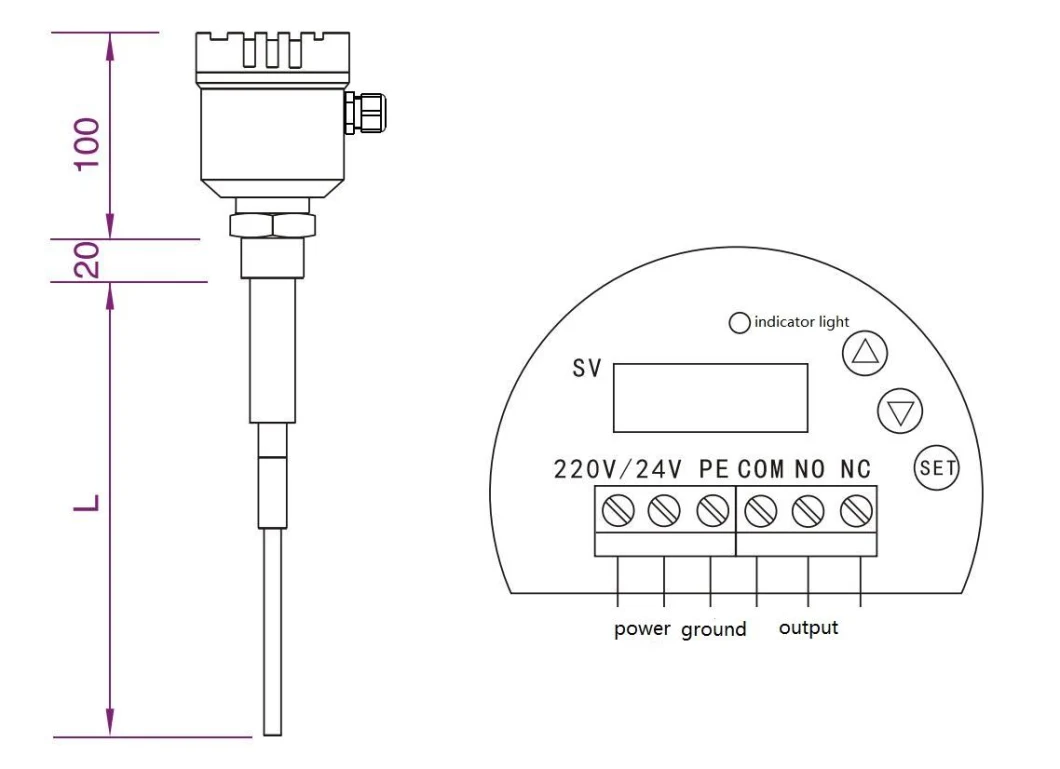

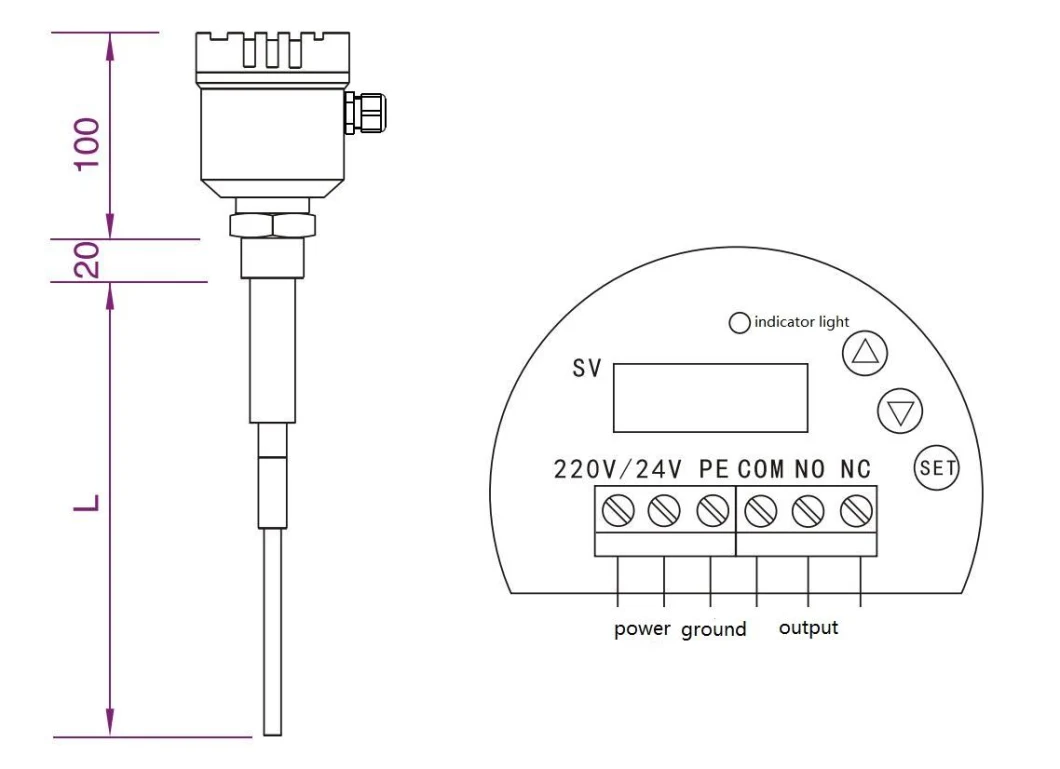

Dimension and wiring connection

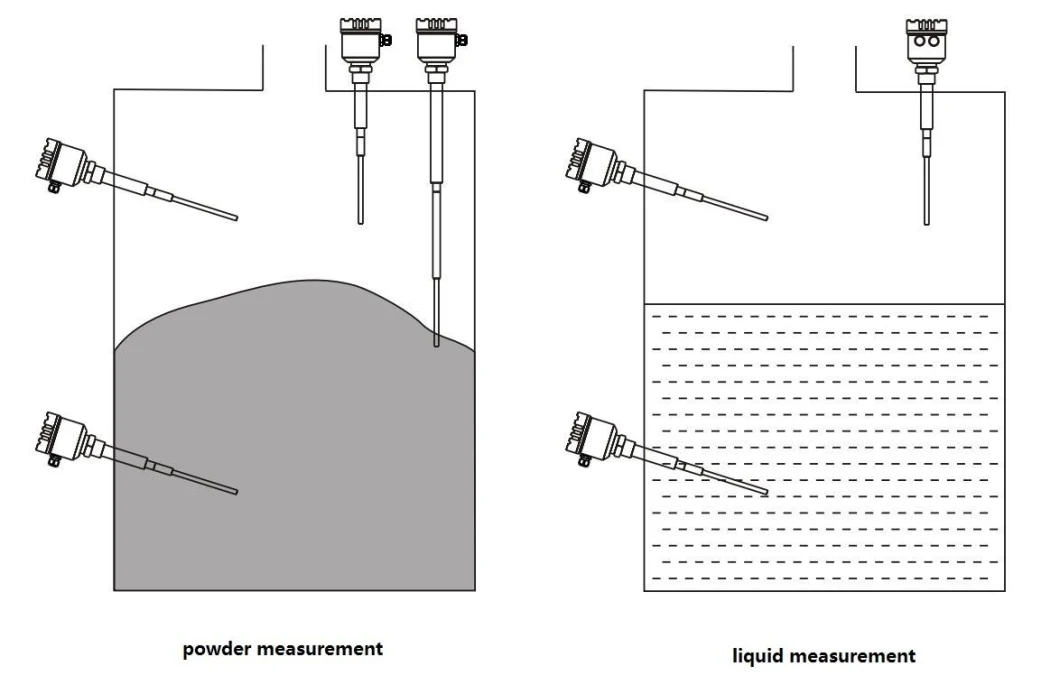

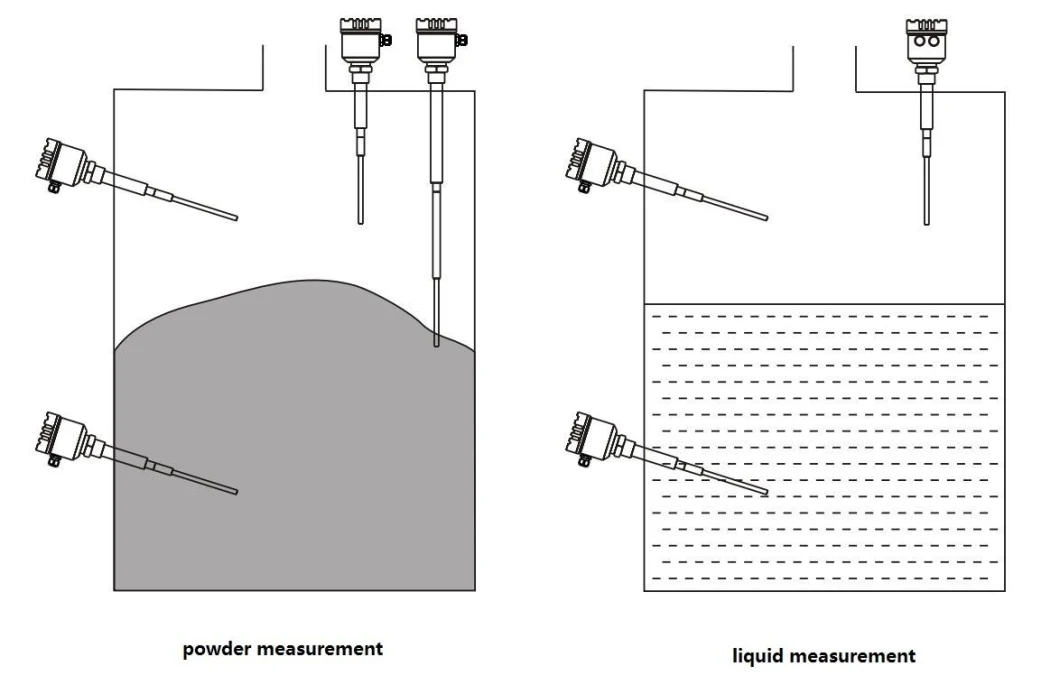

Installation

The RF admittance level instrument is developed from the capacitive level measurement technology. It is a level control detection instrument with anti-hanging material, more reliable, more accurate and wider applicability. RF admittance is a combination of resistive, capacitive, and inductive components.

RF admittance level control technology is to achieve level measurement by measuring the admittance of the measured medium with high frequency radio waves. The difference between RF admittance technology and capacitive technology lies in the diversity of measurement quantity and three-electrode technology. A shield electrode is added between the measurement electrode and the ground electrode to protect the halo electrode from the influence of the hanging material, and the measurement is more stable. Accurate and reliable.

When the position of the material changes, the three-electrode signal processing circuit compares the comprehensive change signal of impedance, capacitive reactance and inductive reactance with the reference signal. When the difference between the two signals reaches a certain level, the output state of the relay changes, thereby detecting Level changes.

Features

- Anti-adhesion: unique circuit design and sensor structure can eliminate the influence of the measurement of the material on the probe, and automatically correct it, avoiding false measurements and signals, and no need to clean the probes regularly;

- Maintenance-free: The switch can be moved by mistake, no mechanical wear, no maintenance required;

- Strong anti-interference: contact measurement, 0.3 second delay can eliminate the influence of material fluctuation;

- Strong adaptability: can detect powder, particles, liquid, viscous, conductive, non-conductive materials.

Application

- Power industry: coal transportation, ash removal system (ash bucket, warehouse pump, ash storage)

- Building materials industry: such as cement plants

- Food industry: flour cans, packaging hoppers

- Pharmaceutical industry: various raw materials storage silos, ingredient mixing tanks, etc.

- Paper industry: sawdust bin, liquid tank

| Probe material | SS304, SS316L, etc. |

| Probe pressure | Max 5.0MPa |

| Sensitivity | 0.5PF; |

| Material temperature | -184 ~ 350 ºC |

| Switching delay | The delay range is adjustable from 0 to 30 seconds; |

| Mounting interface | 1"NPT, 3/4" NPT or customer flange |

| Electrical interface | M20*1.5, 1/2 "NPT |

| Working power | 220VAC, 24VDC; |

| Alarm form | optional upper or lower limit alarm; |

| Output signal | Relay output |

| Contact form | SPDT (1 SPDT); |

| Contact capacity | 220VAC 5A; |

| Power consumption | 2.5W max; |

| Ambient temperature | -40 ~ 80 ºC; |

| Protection level | IP65; |

| Explosion-proof grade | ExiaCT5Ga, ExidCT5Gb |

Selection table

HKD1000-1 2 3 4 5 6

| 1 Type | |||||

| 11- Standard type | 12-Flat plate type | ||||

| 2 Installation | |||||

| S1 - 1-1/4"NPT | S2 - 3/4"NPT | T- Clamp | F - Flange | ||

| 3 Working Power | |||||

| A - 220VAC | B-24VDC | ||||

| 4 Wetted Material | |||||

| P1 - SS304 | P2 - SS316L | F - PTFE | |||

| 5 Working temperature | |||||

| N-80ºC | T - 200ºC | S - 400ºC | |||

| 6 Probe Length (L) | |||||

| Just right the length (mm) | |||||

Dimension and wiring connection

Installation